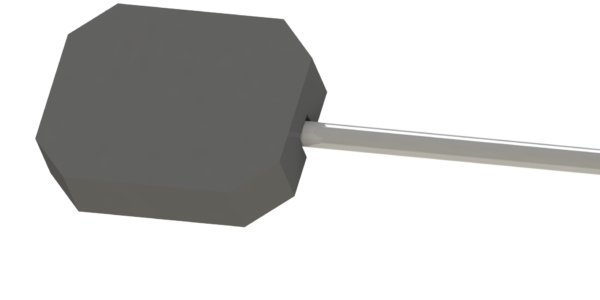

ASC-2016 Magnetic Flux Sensor

Airgap Flux Probe for Rotor Interturn Short Circuit Detection of Turbo Generators.

Description

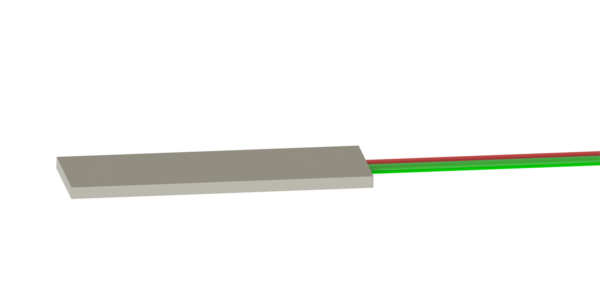

The ASC-2016 Magnetic Flux Sensor is one of the ASC family of airgap search coils to detect faults in the rotor winding insulation of turbo generators.

The body is made out of fiber glass and the sensing element is encapsulated within high temperature epoxy resin. As many machine designs are different, the ASC-2016 Magnetic Flux Sensor is typically custom designed for each type of machine.

The probe is installed on the wedge within the airgap between rotor and stator and the integrated small high temperature cable allows an easy routing outside of the machine. The open wires allows the cable to be laid trough the ventilation holes instead passing it through the endwinding section. The Probe measures the variation of the magnetic flux created from each rotor coil. It withstands up to 2 Tesla and is designed to operate for more than 155°C. The high temperature signal cable can be permanently used for up to 155 °C. If longer signal cables than 10m are required, the probe is delivered with a signal driver.

Key Features Comparison Table

- Individually designed to machine construction.

- High Temperature range, very small signal cable allows the cable to be laid through ventilation hole.

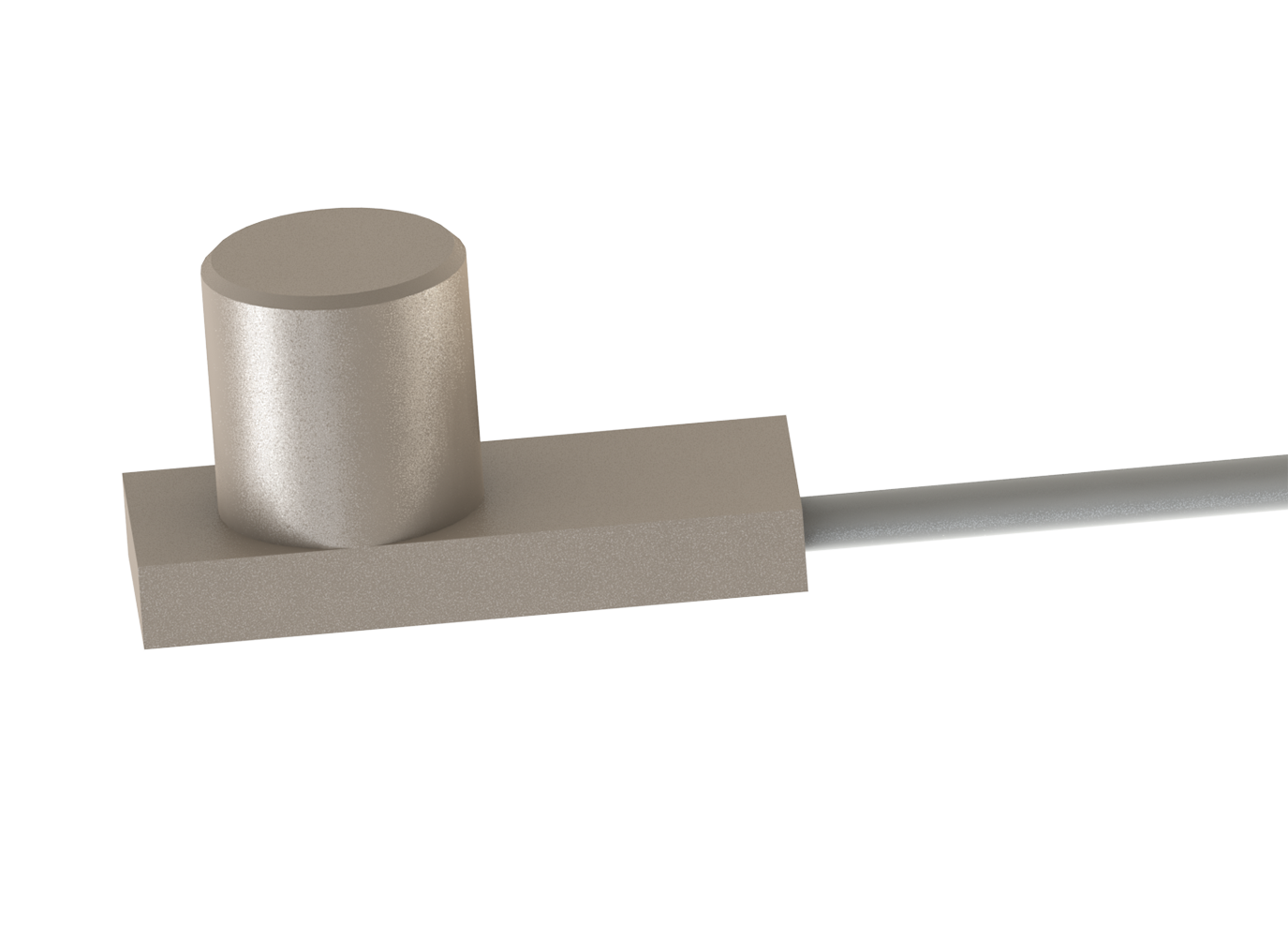

Magnetic Flux Sensor ASC- 2016 Dimensions

Sensor

- Dimensions 50x15x2mm

- Case Material: Fiber Glass

- Cable Length 5 or 10m

- Cable Diameter 1.6 / 3mm

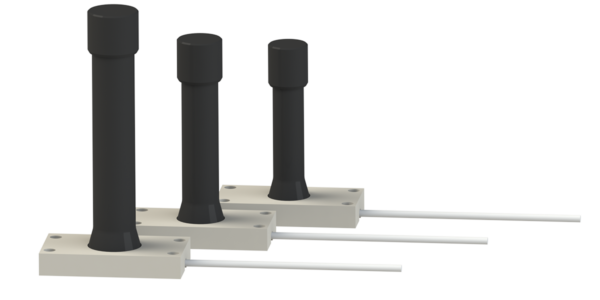

Driver

- Dimensions: 130 x 64 x 38mm

- Case Material: Diecast Aluminium

- Signal Connection 4 pole M12 Connector