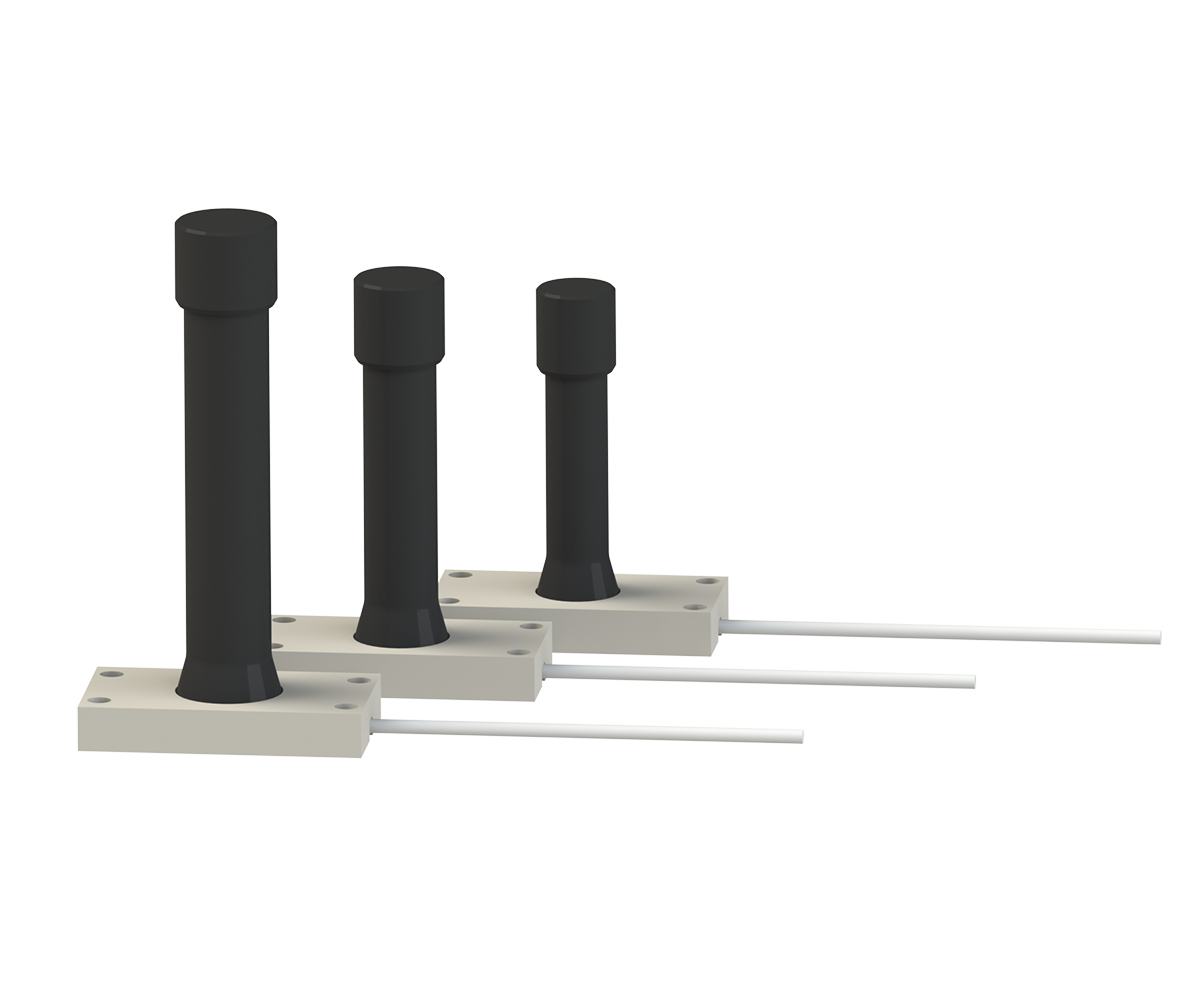

ASCF Flexi Flux-3000 Magnetic Flux Sensor

Airgap search coils used to detect faults in the rotor winding insulation of turbo generators

Description

The ASCF Series Flexi Flux is one of the ASC family of airgap search coils used to detect faults in the rotor winding insulation of turbo generators.

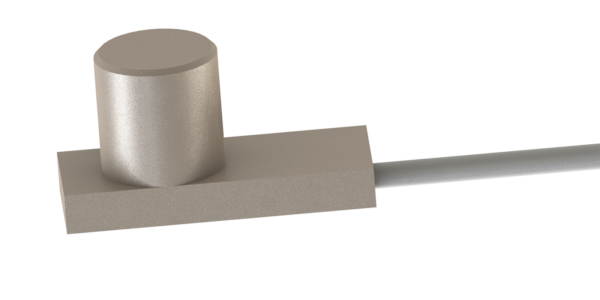

The probe is installed on the wedge within the airgap between rotor and stator, the integrated small high temperature cable allows an easy routing outside of the machine.

The open wire design allows for cables to be laid trough the ventilation holes instead of passing it through the endwinding section.

The Probe measures the variation of the magnetic flux created from each rotor coil. The sensor component is integrated within a flexible housing, allowing a safe installation of the rotor, even the retaining ring is bigger than the rotor diameter. The ASCF-Series Flux Probe withstands up to 2 Tesla and is designed to operate for up to 155°C. The integrated signal cable is available in length of 5, 10 or 15m and if If longer signal cables are required, a signal driver is available.

Key Features Comparison Table

Magnetic Flux Sensor ASCF – 125 Dimensions

- Base Dimensions 25 x 50mm

- For airgaps: 20..40mm

Magnetic Flux Sensor ASCF – 325 Dimensions

- Base Dimensions 25 x 50mm

- For airgaps: 35..65mmNominal Voltage: 12kV rms

Magnetic Flux Sensor ASCF – 528 Dimensions

- Base Dimensions 28 x 50mm For airgaps: 50..80mm

- Nominal Voltage: 17.5kV rms