UDL-8000 Condition Monitoring Controller

Central UDL controller with sensor interfaces and signal conditioning units to support interchangeable plug in modular design based on individual condition monitoring requirements.

Description

The UDL-8000 Condition Monitoring Controller serves as the central component of our modular design by harnessing a one or many of our interchangeable plug in modules based on your condition monitoring requirements.

The UDL-8000 is based on a central controller with sensor interfaces and signal conditioning modules. This modular design approach facilitates a highly customisable, cost effective solution for all major machines assets and monitoring techniques:

- Stator and rotor insulation of rotating machines

- Monitoring of busducts

- High voltage cables

- High voltage transformers as well as air insulated and gas insulated switchgears.

In order to privide a greater flexibility, the UDL-8000 is available in various sized enclosure, generally for DIN -Rail or panel mounting. Optionally the system is also available as 19″ Rackmount solution.

Implementation Example

Depending on the customer requirements, individual application specific systems can be built such as standalone flux monitoring system for turbo generators or standalone acoustic partial discharge monitoring for large power transformers. Whenever multiple parameters are monitored, the system can be built up as a combined solution, sharing the central CPU controller for multiple applications, where each parameter is monitored sequentially. For applications where true simultaneous acquisition over multiple parameters is required, multiple UDL-8000 CPU controllers can be integrated into the same enclosure.

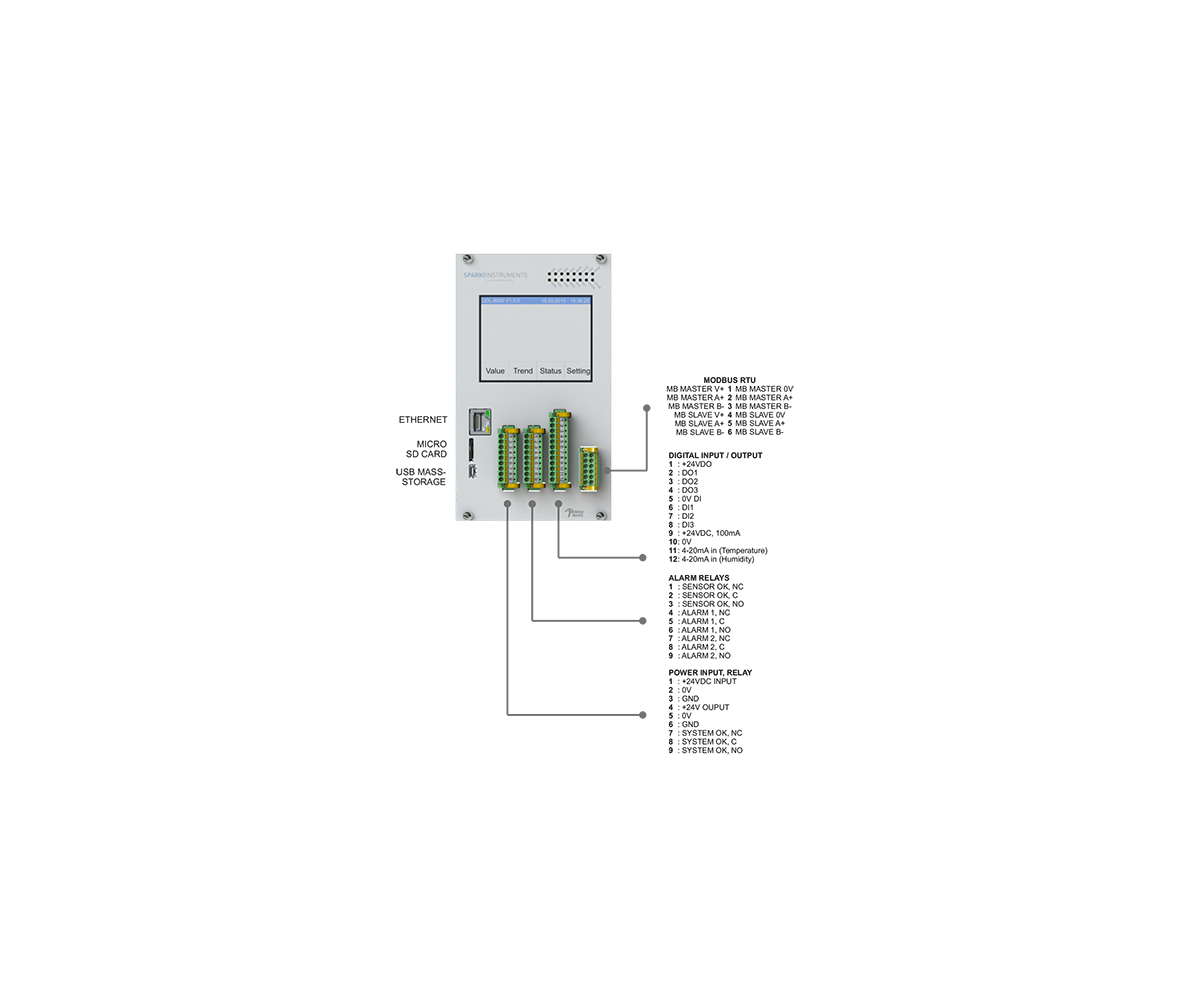

The UDL-8000 Central CPU controller includes the basic interfaces such as relay contacts and Modbus RTU. The relay contacts can be shared with any parameter acquired through the modules. Whenever additional interfaces are required such as individual relays or analogue inputs or outputs (4-20mA). the UDL-8000 system can be extended with the desired modules. Each UDL-8000 Controller can be equiped with up to eigth modules, either input modules or output modules.

Key Features

One of the UDL-8000 key features is the flexibility the system offers. Standard off the shelf controllers, modules and software packages allows us to provide a customer specific solution. The UDL-8000 can be offered a dedicated, individual standalone system with single functions, up to a completely integrated system.

For Rotating Machines:

- Endwinding Vibration Monitoring

- Rotor Flux Monitoring Rotor Short Turn Detection

- Shaft Voltage and Shaft Voltage Monitoring

- Stator Insulation Partial Discharge Monitoring

- Stator Core Temperature Monitoring

- General Process Parameter Recording

For Bus Ducts:

- Partial Discharge Monitoring

- Ozone or Insulation Gas Monitoring (using dedicated Gas Detectors)

- Ambient Condition Monitoring

- Temperature Monitoring

For Power Cables:

- Partial Discharge Monitoring of Cables, Cable termination and Joints

- Temperature Monitoring

For Power Transformers:

- Acoustic Partial Discharge Monitoring

- UHF Partial Discharge Monitoring

- Temperature Monitoring

- Structural Vibration Monitoring (Tank / Core)

- Power Analysis

- Cooling Fan Monitoring

For Air Insulated Switch Gears:

- TEV Partial Discharge Monitoring

- Ozone Gas Monitoring

For Gas Insulated Switch Gears:

- Acoustic Partial Discharge monitoring

- UHF Partial Discharge Monitoring

Hardware Modules:

The UDL-8000 CPU controller supports up to eight modules, were each module has typically eight acquisition channels. For partial discharge measurement applications the UDL-8000 CPU controller C2 is required, it includes six additional partial discharge acquisition channels.

- M8001 8 ch voltage measurement module with 1x & 2x integrator, 1x reference input

- M8002 8 ch standard voltage and current measurement module

- M8003 8 ch Vibration sensor module, constant current, 1x integrator

- M8007 8 ch RTD temperture module

- M8008 Temperature chain monitoring module, 4 sensor chains, 64 sensors per chain

- M8009 Magnetic flux monitoring module, 1x reference input, 2x flux probe input

- M8011 8 ch 4-20mA output module

- M8012 3 ch power analyzer module, 3x voltage, 3x current

- M8013 8 ch Relay Module SPDT

- M8014 3 ch UHF PD module, 1x RF, 1x Ref

- M8015 8 ch digital input

- M8016 Shaft current and shaft voltage module, 1x reference, 5x 4-20mA input

- M8017 Transformer Bushing monitoring module, 3x tan delta, 1x reference

- M8018 1 ch UHF module, 1x RF, 1x ref

- M8019 5 ch Partial Discharge Monitoring Module (Multiplexed), 16kHz .. 300MHz

- M8020 5 ch Partial Discharge Monitoring Module (Simultan), 16kHz .. 300MHz

- M8021 4 ch Ultrasonic Partial Discharge Module, 4x AEPD, 1x RF PD, 1x ref

- M8022 6 ch Partial Discharge Monitoring Module, 40MHz .. 350MHz

Software Modules and Firmware Package

In order to simplify the handling and the configuration of the system, the UDL-8000 is based on dedicated application specific software packages built into the systems operating system.

A simple selection of the desired application allows Sparks Instruments or the customer to configure the system with just a few mouse clicks. The UDL-8000 is supplied with a single configuration software to be used for all types of applications and Modules.

The following Software Packages are available:

- PDSEQ Sequential partial discharge acquisition, 8 bit prpd patterns, pulse height distribution

- PDSIM Simultaneous partial discharge acquisition, 8 bit prpd patterns pulse height distribution, TR pattern, CMR

- PDBAS Basic partial discharge monitoring, 6bit prpd patterns, pulse height distribution

- PDAE Simultaneous partial discharge monitoring for acoustic pd measurement

- SUI Shaft voltage and shaft current monitoring

- FLM Flux monitoring module

- EWM Endwinding Vibration Monitoring

- PAM Power Analyzer Module

- TAN3 Bushing Monitoring

- BVIB Basic vibration monitoring

- RTD Temperature Monitoring

Whenever the UDL-8000 is running multiple applications sequentially and is extended with output Modules represented as digital outputs, Relays and 4-20mA Outputs, each measurement channel can be freely assigned to any of the output channels. There is no limit of extension modules except the maximum of eight modules per controller.

Simultaneous Acquisition and Distributed Acquisition

If the UDL-8000 system is used with a single application, all UDL-8000 systems can be synchronised allowing a simultaneous acquisition over multiple systems installed over multiple locations.

This feature is typically used, whenever large objects are monitored such as busducts or gas insulated switchgears. The group of systems are assigned to one master system which triggers the acquisition of the slave systems.

When connected to the TMS-2000 Data Server, all raw data is streamed into the database simultaneously. As each data set is assigned to a timestamp and the trigger information, the raw data can further be analysed simultaneously. For standard server applications, up to 16 UDL-8000 can be synchronised together. This offers up to 128 simultaneous acquired voltage channels or up to 80 partial discharge channels.

The system configuration, channel descriptions, alarm events, parameter trend data and raw data are stored into an SQL based database which allows access to third party applications.

This means the complete monitoring system can be easily integrated into the plant monitoring system or third party software application.

Networking and SCADA interface

All UDL-8000 Systems are compatible with the Partial Discharge Monitoring Systems of the TMS-Series and can be connected via the Ethernet network to the same TMS-2000 Data Server.

Depending on the quantity of UDL-8000 Systems and the different locations, the UDL-8000 systems can be connected to multiple TMS-2000 Data Servers. Each Data server can be replicated via a star like replication server located either within the same plant or via Internet or Intranet via multiple plants.

Beside the own Ethernet protocol used for the communication between the UDL-8000 monitoring systems and the TMS-2000 Data servers, each UDL-8000 has an additional Modbus RTU slave interface, for the intercommunication to the SCADA system. This allows the acquired data to be published to the SCADA system or to collect process parameters of the machine to the individual monitoring systems. For SCADA systems using other interfaces and protocols as e.g. Modbus TCP, Profibus DP or IEC61850, external interface gateways are used through the Modbus RTU slave.

The UDL-8000 controller offers an additional Modbus RTU Master interface, allowing the collection of data from third party devices, as e.g. vibration monitoring systems or dissolved gas analyzer (DGA).