Early fault detection is critical in avoiding major component failure and unplanned downtime. Sparks Instruments design and manufacture the sensors, monitoring instruments, acquisition systems and diagnostic tools to reveal the actual condition of your Turbo Generator.

We offer a number of different monitoring options that you can select from: partial discharge monitoring, rotor flux monitoring, shaft voltage and current, and temperature.

Our solutions provide plant operators with an centralized, holistic view of the Turbo Generator and all of it’s major components by visually overlaying key data gathered by any or all of the above monitoring options onto a single graphical representation of your generator. This allows you to monitor the entire Generator and it’s electrical components on the one screen.

This information is key in supporting early fault detection and reliably informs maintenance planning over the machines life-cycle as it ages. Machine manufactures and plant operators are provided with vital information during site acceptance phase of new and refurbished machines.

This greatly reduces the risk of failure and unplanned downtime..

-

Expert TMS-5141 Partial Discharge Monitor

- Standalone, continuous partial discharge monitoring system with automatic data acquisition, storage, diagnostics, and trending. Sensor Compatibility: HFT Series Partial Discharge Sensor HFTC Series Partial Discharge Sensor PDC Series Partial Discharge Sensor

-

Escort TMS-6141 Partial Discharge Monitor

- Portable, periodic, standalone, partial discharge monitoring system with manual or automatic data acquisition, storage and diagnostics. Sensor Compatibility: HFT Series Partial Discharge Sensor HFTC Series Partial Discharge Sensor PDC Series Partial Discharge Sensor

-

Basic TMS-5041 Partial Discharge Monitor

- Partial Discharge Analysis for Rotating Machines. Simple, continuous partial discharge monitoring system with manual data storage. Sensor Compatibility: HFT Series Partial Discharge Sensor HFTC Series Partial Discharge Sensor PDC Series Partial Discharge Sensor

-

UDL-8000 Condition Monitoring Controller

- Central UDL controller with sensor interfaces and signal conditioning units to support interchangeable plug in modular design based on individual condition monitoring requirements.

-

UDL-M8009 Magnetic Flux Monitor

- Magnetic Flux, Rotor Flux monitoring plug-in module for rotor winding with automatic data acquisition, diagnostics and storage. Sensor Compatibility: ASC-2016-Magnetic-Flux-Sensor Series ASC-2520-Magnetic-Flux-Sensor Series ASCT-5015-Magnetic-Flux-Sensor Series ASCF-Flexi-Flux-Sensor Series

-

TMS-2000 Condition Monitoring Database

- A central view of your machine's diagnostics on one screen.

-

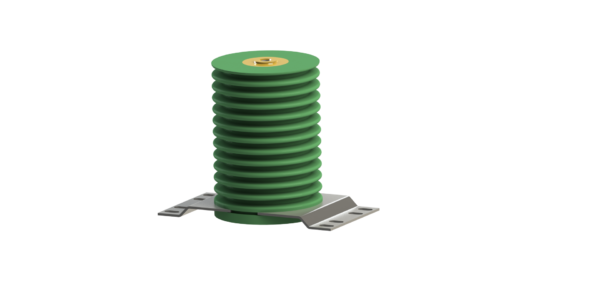

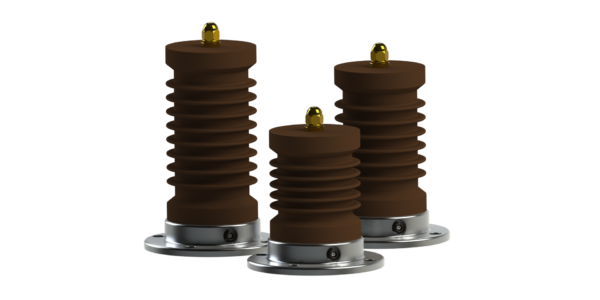

EMPDC Partial Discharge Sensor Coupling-Capacitor

- EMPDC Epoxy-Mica Partial Discharge Sensor Coupling-Capacitor.

-

PDC Partial Discharge Sensor Coupling-Capacitor

- Coupling capacitor 80pF or 1000pF partial discharge online sensor.

-

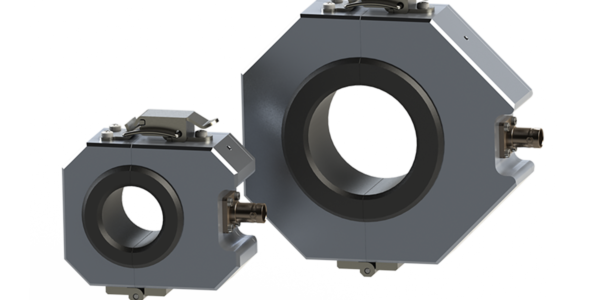

HFTC High Frequency Current Transformer

- Partial Discharge High Frequency Current Transformer - Clamp on, clamp off for live machine fittings ø30mm and ø50mm

-

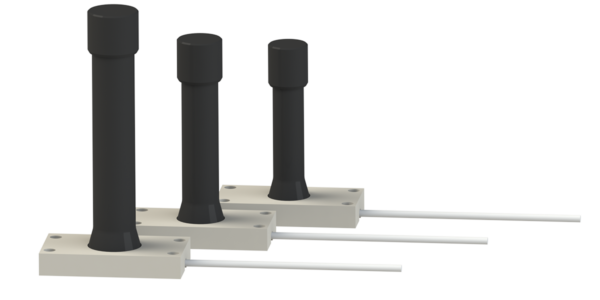

HFT Partial Discharge Sensor HF-TC

- Partial Discharge High Frequency Current Transformer - ø17mm and ø24mm

-

ASCF Flexi Flux-3000 Magnetic Flux Sensor

- Airgap search coils used to detect faults in the rotor winding insulation of turbo generators

-

ASC-2016 Magnetic Flux Sensor

- Airgap Flux Probe for Rotor Interturn Short Circuit Detection of Turbo Generators.

-

ASC-2520 Magnetic Flux Sensor

- Airgap Flux Probe for Rotor Interturn Short Circuit Detection of Hydro Generators, Turbo Generators and High Voltage Machines.

-

ASCT-5015 Magnetic Flux Sensor

- Airgap Flux Probe for Rotor Interturn Short Circuit Detection of Hydro Generators, Turbo Generators and High Voltage Machines.